Construction manual of a biogas digester by T.H. Culhane

Here is the description of the system, the basic principles are very simple, use the things you

find in your surroundings.

15. Put an elbow, ½” valve and hose adaptor on the ½” tank adaptor and connect to ½” Here is the description of the system, the basic principles are very simple, use the things you

find in your surroundings.

|

| 1. Cut the top off at a 2.500 liter water tank.You have now made the stomach of your “sacred cow”. |

|

| 2. Drill 2” hole at bottom of tank and 1” hole at top of tank. |

|

| 3. Put tank adaptors in holes (threaded pipewith rubber gasket and locking nut, sometimes called bulkhead fittings (check aquarium shop). |

|

| biogas digester |

|

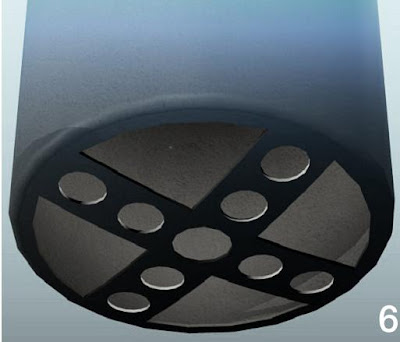

| 6. Cut 8 holes slightly larger than 2” in bottom. |

|

| 7. Burn or drill a ½” hole in the top of the gas collector tank near the side as shown. |

|

| Put a ½” tank fitting in this hole |

|

| 9. Put small stones at bottom of stomach tank as homes for bacteria, but do not block or go higher than the output of the feeding pipe. |

|

| 11. Cut 8 2” pipes slightly shorter than the height of the gas collector and cut holes in them like a church organ to let food in and gas out. |

|

| 12. Fix a piece of ½” pipe (A) through one end of the 2” pipe and melt its ends so it flares out and can´t fall out of the 2” pipe. |

|

| Add caption |

plastic tube.

16. Wait 3 weeks or so with valve closed until gas collector starts to rise. Release all gas to air

and let it rise again. Release all gas in case it has oxygen in it.

17. The third time tank rises, try to light gas coming out. If it doesn’t light it has too much CO

2in it. Release it and let it rise again. One day it will light as CH2concentration rises.once it lights you can start slowly feeding.

18. When you connect the outcoming gas tube with your cooking place, make sure that a simple “water trap” is included, so that the pipes do not become blocked by condensing water.

| |

| download diagram |

Related Post:

Biogas Plant Construction Manual Fixed-dome Digester

Constructing a Floating Drum Biogas Digester Part 4

Constructing a Floating Drum Biogas Digester inlet Part 3

Constructing a Floating Drum Biogas Digester outlet Part 2Step by Step Guide to Constructing a Floating Drum Biogas Digester Part 1