Construction and use of a biogas digester  |

| biogas digester |

Construction and use of a biogas digester Biogas systems can be built on any scale: small and simple for a single household, or large and industrial for a whole municipality. In

Tamera we are interested in biogas digesters appropriate for a village or community

kitchen; we strive to make these with inexpensive, widely accessible materials and technology.As previously stated, biogas consists of about two third methane and one third CO2, with some water vapor and trace gasses (principally H2 S) and as such, without any alteration or purification, it can be used in all appliances made for natural gas for example cookers and water and space heaters and electric gensets with minimal modifications.

A basic biogas digester consists of a tank in which the organic material is digested, combined with a system to collect and store the biogas produced. The digesters can be quite simple, and the details vary depending on available materials and the needs of the community. Our biogas digester, built in cooperation with T.H. Culhane from Solar C³ITIES e.V., consists of a cylindrical 3000 liter tank, open on top, in which the organic material is digested. A second, slightly smaller tank is placed in the larger tank, upside-down. As biogas is produced, the inner tank fills with gas and rises, telescoping out of the outer tank. As biogas is removed for use, the inner gas storage tank sinks back into the larger, outer tank. In this system, the inner tank acts as both storage, and as a lid for the digester tank. The gap between the tank walls is narrow enough to prevent significant quantities of oxygen from entering the digester, which would kill the anaerobic bacteria that produce the methane.

The amount of biogas lost though the gap is negligible. 3000 liter digester is typically “fed” around 40-60 liters of biomass daily a few full buckets of ground up organic waste mixed with water and produces enough gas for several hours of cooking per day. The main sources of biomass are food scraps and kitchen waste. Non-woody garden waste is also appropriate.Before being fed into the digester tank, the biomass is mechanically macerated — chewed up — with an

“Insinkerator” garbage disposal.Nowadays these “waste disposal” machines are being rebranded as “feedstock preparation devices”and we call them “compost companions” because they can be used to prepare organic garbage for use in both anaerobic and aerobic decomposition processes.Grinding allows the bacteria to access and digest the organic material more easily; in an anaerobics ystem the transformation into gas and fertilizer can take as little as 24 hours while in an aerobic compost pile the transformation into soil can take as little as three to six days instead of months.For our biogas digestor a slurry of ground biomass and warm (40°C) water is poured into the tank inlet funnel. The inlet for the digester leads down to the bottom center of the digester tank. The digested organic material leaves as a high-quality liquid fertilizer, through an outlet near the top of the outer digester tank. At the top of the inverted, inner tank, there is an outlet for the biogas. Before normal operation, the biogas digester must be “started.” This is done by preparing a 1:1 mixture of fresh animal manure and water, and allowing this to ferment anaerobically for several weeks. The volume of this mixture should be around 200 liters for a 3000 liter digester or roughly 30-40 kg of animal manures per cubic meter of digestor tank space. Less can be used but it would simply take longer to establish the colonies of bacteria to enable feeding (feeding only starts once first flammable gas is produced).The slurry can be prepared in a seperate container or in the digester tank. The manure contains the naturally-occurring bacteria that digest organic matter and produce methane. Note that unlike in cheesemaking or yoghurt making biogas digestors do not rely on one strain of bacteria but depend on a balanced ecology of many different types of microbes – hydrolytic, acidogenic, acetogenic and methanogenic.

Fortunately these are all found in animal manure and even lake mud. Essentially any animal wastes can be used cow, horse, pig, and others; alone or mixed.Human excreta can be used as well, although in this case the fertilizer output of the digester should only be used on trees, or in other appropriate applications. Once the manure-mixture is producing flammable gas, feeding of the digester with biomass can begin. It is best to begin gradually, for example with 1/3 of the expected feeding for the first week, 2/3 for the second, and then onto a normal feeding regime. The maximum ratio is about 25 liters of feedstock slurry for every 1000 liters of digestor space.During normal operation, manures can still be included in the feed stock. Most energy has already been extracted from manure, but it can help maintain or replenish bacteria populations in the digester and help balance the pH. The pH and temperature of the digester will affect its performance. Biogas digesters prefer to be at a neutral pH; overfeeding with fats and carbohydrates and certain acidic feedstocks can lower the pH and damage bacterial populations while overfeeding with proteins (animal or vegetable) or nitrogen-rich materials (for example chicken droppings, feathers, skin, hair or slaughterhouse waste) can raise the pH and also damage the bacterial consortia. If one thinks of the digester simply as a stomach (for this is where the bacteria originated) and gives it a balanced nutrition, or if one thinks of it as a liquid compost pile and observes the usual C:N ratio of about 25 to 1, the system should last indefinitely. But if the bacterial ecology does get out of balance, one can simply restore the pH to neutral, add more manures, and start over, so it isn’t difficult to recover from improper feeding and one shouldn’t fret too much about “damaging” the system. Fortunately every one of us carries in our own guts all the materials we need to get things working again, and for this reason biogas systems are truly the easiest and most democratic of all forms of renewable energy. High temperatures can kill bacteria; low temperatures may cause them to become dormant. Different methane-producing bacteria respond to temperature differently; some prefer cooler temperatures as low as 17°C-20°C (psychrophilic). Others thrive at higher temperatures around 57°C (thermophilic). On the whole, however, biogas digesters well-suited to temperate climates work best at temperatures around 37°C (mesophilic). In most non-tropical climates, it may be worthwhile to insulate and heat the digester tank, for example with a solar hot water system. It can be helpful to put lake mud in the digester to populate the colder bottom regions with psychrophilic (cold-adapted) microbes.

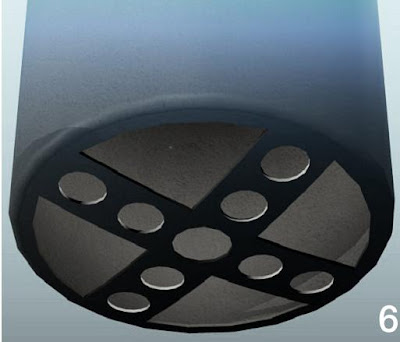

The methane-producing bacteria are not adapted to floating free in a tank; they evolved to live in an

animal’s stomach, where they attach to surfaces while being exposed to flows of digestible material.

These conditions can be recreated by covering the bottom of the tank with porous stones or gravel and by

building high-surface-area “hi-rise” structures inside the digester tank (we call these “microbial motels”!).

Vertical structures which permit bacteria to inhabit all the temperature zones of the tank increase

efficiency – water separates into thermal layers with the coldest water accumulating at the bottom of the tank

and the warmest water at the top. Unfortunately, most biodigestors rely on bacteria living in sludge granules

on the cold tank floor to do most of the work.

By providing bacterial “elevators” or vertical “fuel rods” we give our “pet microbes” a chance to find the

zone within the thermocline most suited to their needs. We often build our “microbe motels” with recycled plastic tubing, striving for minimum impact on the flow of gasses and slurry in the tank. We find verticle plastic pipes with holes cut in them to let food in and bubbles out to work well (think of a pipe organ) but vertically strung nets also work as does filling the tank with “bio-blocks” or “bio-balls” or other typical pond filtration media used to encourage bacterial growth. One doesn’t need to buy them – we make them by chopping up old corrugated plastic electrical conduit; in Palestine our colleagues throw in the husks of almonds and pistachios; the idea is simply to have floating media upon which bacteria can form their active biofilms. The more surface area in the tank the larger your bacterial population and theoretically the more you

can feed them; the more biofilms there are the more efficient the bacteria making them up can work and

produce more gas and fertilizer (bacteria form what have been likened to “microbial cities” in their biofilms

where different regions engage in specialized functions). As Dr. Anand Karve, inventor of the ARTI India Telescoping biogas system we have adapted, said: “after all, we are talking about bacteria for heaven’s sake - bacteria that can be found anywhere and everywhere, even in our own stomachs!”

Construction manual of a biogas digester by T.H. Culhane