Renewable Energy from Kitchen Waste

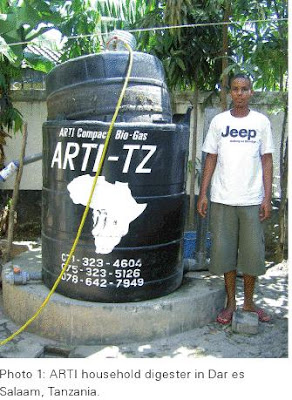

ARTI compact biogas plant (Photo 1) in Dar es Salaam, Tanzania in 2008. It assessed the plant’s suitability to treat kitchen waste at household level in urban areas of developing countries. In collaboration with the Ardhi University of Dar es Salaam, an ARTI biogas plant was installed, operated

and monitored on the University campus for four months in 2008. The biogas plant was fed daily with 2 kg of food leftovers (TS:24 %) from the University canteen as well as vegetable and fruit waste (TS:10 %) from a nearby market. A daily quantity of 2 kg organic waste generated by a five-member Tanzanian household

seems a realistic figure. According to the results obtained, the system seems robust in terms of structural and biological stability and very effective in reducing the organic load (84 %COD removal). The digester effluent is an odourless, high-quality fertiliser valued in horticulture. The average daily gas production amounted to 290 L/d and 130 L/d when fed daily with 2 kg (wet weight) of food waste or market waste. Assuming that a tanzanian household produces1 kg of food leftovers and 1 kg of fruit and vegetable peelings, these 2 kg of kitchen waste generate 200 L of biogas (61 %CH 4) equivalent to a 45-min burning period. This represents about 1/3 of the average cooking time of 2.5 h per day and family (five-member household). An aver-

age household using annually 1008 kg of charcoal can therefore save one third of the charcoal (336 kg) or an equivalent of TZS 276 000 (Euro 168). As the ARTI system is sold for TZS 850 000 (Euro 507), its

amortisation period amounts to roughly three years. However, since the investment costs are rather high, its widespread implementation is limited. Further experiments revealed that with some additional logistical and operational efforts, the daily feeding load could gradually be increased to 5 kg, and produce 670 L/d of gas or150 min cooking time.Though system performance in terms of gas production and removal of organic

material is excellent, digester design has to be optimised. The most essential technical improvements concern digester and gasholder size. The current design leadsto a gas loss of about 22 % of the total digester area as a result of the unfitting rim between digester and gasholder. An improved fit between these two elements

would considerably reduce atmosphericloss of biogas.Furthermore, a household survey indicates that most of the installed systems in Dar es Salaam are poorly operated and maintained. Operating instructions and follow up service provided by ARTI TZ were insufficient and need to be improved. Therefore, a follow-up service will have to be provided by ARTI-TZ after plant installation. Following this survey, ARTI-TZ has already made great efforts to improve its service and is currently distributing a customer manual in English and Kiswahili. Although there is room for improvement, the ARTI biogas system proved technically and environmentally suitable. However, to render this system affordable to a wider public in Tanzania, the price

would have to come down considerably. ARTI is not the only household biogas system available on the market. A similar system has been developed by BIOTECH in India. However, unlike ARTI, ithas its own manufacturing unit of digesters made of fibreglass reinforced plastic.The system is very widespread in South

India, where 12 000 household digesters have already been implemented. By tightly fitting digester and gasholder, gas loss through the rim could be reduced. The latest biogas model is even equipped with a water jacket to prevent atmospheric biogas loss.The experience gained in Tanzania and India reveals the great potential of anaerobic digestion of kitchen waste at house hold level. Since BIOTECH is already oper-

ating numerous biogas plants in schools, hotels and markets [2], this technology also seems very promising at institutional level. As the ARTI system can be scaled up, a follow-up project is now focusing on an ARTI biogas system with three 4 000-L digesters, already operating in a secondary school in Dar es Salaam since August 2008. Contact: yvonne.voegeli@eawag.ch

Anaerobic digestion of organic household waste in developing countries is seen as a new treatment option to enhance waste management and provide households and institutions with biogas arenewable, clean source of cooking energy. Yvonne Vögeli, Christian Lohri

ARTI compact biogas plant (Photo 1) in Dar es Salaam, Tanzania in 2008. It assessed the plant’s suitability to treat kitchen waste at household level in urban areas of developing countries. In collaboration with the Ardhi University of Dar es Salaam, an ARTI biogas plant was installed, operated

and monitored on the University campus for four months in 2008. The biogas plant was fed daily with 2 kg of food leftovers (TS:24 %) from the University canteen as well as vegetable and fruit waste (TS:10 %) from a nearby market. A daily quantity of 2 kg organic waste generated by a five-member Tanzanian household

seems a realistic figure. According to the results obtained, the system seems robust in terms of structural and biological stability and very effective in reducing the organic load (84 %COD removal). The digester effluent is an odourless, high-quality fertiliser valued in horticulture. The average daily gas production amounted to 290 L/d and 130 L/d when fed daily with 2 kg (wet weight) of food waste or market waste. Assuming that a tanzanian household produces1 kg of food leftovers and 1 kg of fruit and vegetable peelings, these 2 kg of kitchen waste generate 200 L of biogas (61 %CH 4) equivalent to a 45-min burning period. This represents about 1/3 of the average cooking time of 2.5 h per day and family (five-member household). An aver-

age household using annually 1008 kg of charcoal can therefore save one third of the charcoal (336 kg) or an equivalent of TZS 276 000 (Euro 168). As the ARTI system is sold for TZS 850 000 (Euro 507), its

amortisation period amounts to roughly three years. However, since the investment costs are rather high, its widespread implementation is limited. Further experiments revealed that with some additional logistical and operational efforts, the daily feeding load could gradually be increased to 5 kg, and produce 670 L/d of gas or150 min cooking time.Though system performance in terms of gas production and removal of organic

material is excellent, digester design has to be optimised. The most essential technical improvements concern digester and gasholder size. The current design leadsto a gas loss of about 22 % of the total digester area as a result of the unfitting rim between digester and gasholder. An improved fit between these two elements

would considerably reduce atmosphericloss of biogas.Furthermore, a household survey indicates that most of the installed systems in Dar es Salaam are poorly operated and maintained. Operating instructions and follow up service provided by ARTI TZ were insufficient and need to be improved. Therefore, a follow-up service will have to be provided by ARTI-TZ after plant installation. Following this survey, ARTI-TZ has already made great efforts to improve its service and is currently distributing a customer manual in English and Kiswahili. Although there is room for improvement, the ARTI biogas system proved technically and environmentally suitable. However, to render this system affordable to a wider public in Tanzania, the price

would have to come down considerably. ARTI is not the only household biogas system available on the market. A similar system has been developed by BIOTECH in India. However, unlike ARTI, ithas its own manufacturing unit of digesters made of fibreglass reinforced plastic.The system is very widespread in South

India, where 12 000 household digesters have already been implemented. By tightly fitting digester and gasholder, gas loss through the rim could be reduced. The latest biogas model is even equipped with a water jacket to prevent atmospheric biogas loss.The experience gained in Tanzania and India reveals the great potential of anaerobic digestion of kitchen waste at house hold level. Since BIOTECH is already oper-

ating numerous biogas plants in schools, hotels and markets [2], this technology also seems very promising at institutional level. As the ARTI system can be scaled up, a follow-up project is now focusing on an ARTI biogas system with three 4 000-L digesters, already operating in a secondary school in Dar es Salaam since August 2008. Contact: yvonne.voegeli@eawag.ch